RFID Lab Asset Management Software

State-of-the-Art RFID Solutions for Laboratories

Companies in various verticals including Electronics, Life Sciences, Medical Devices, Automotive, and Manufacturing have large R&D departments. This means they have a large number of labs spread across buildings, business units and geographies. These organizations make significant investments in R&D equipment. However, there never seems to be enough quantities of every type of equipment. That is why lab asset management becomes essential. Labs need to make judicious decisions on using their funds either to increase the number of existing R&D equipment or to reserve them to purchase other types of equipment to do R&D on new product lines for the company.

RFID Lab Asset Management Software to Locate Equipment

Due to the limitation of funds, R&D departments always have to grapple with a chronic shortage of equipment in the labs. Engineers and scientists routinely 'borrow' equipment from one lab with the intention of returning them. However, that does not happen. This causes a challenge to lab managers and asset managers who are tasked to control and track equipment in labs.

Lab managers are on the hook to locate equipment when it is needed on a project or an experiment. Along with the lab manager's time looking for equipment, expensive engineer/scientist time is also spent tracking down the equipment. Not only do costs rack up, but also high profile and critical projects timelines can be impacted due to unavailability of equipment.

AssetPulse's RFID lab asset management software helps lab managers to easily and instantly locate lab equipment. With a click of a button, lab asset managers can get the exact location of the equipment, who is using it and for how long, and other details about the equipment.

RFID Lab Equipment Management Software to Locate Equipment for Calibration

Further exacerbating matters is the criticality of locating equipment, when it is due for calibration. There can be severe consequences if 'past due calibration' equipment was used in a project or experiment - the antithesis of a GMP Lab. Lab managers spend hundreds of hours every year, searching for equipment that is due for calibration. AssetPulse's RFID lab equipment management software helps lab managers to not only locate the equipment quickly but also get real-time alerts on equipment that are due for preventive maintenance and calibration.

RFID Lab Equipment Tracking Software for Clean Room Equipment Tracking

Clean rooms have a strict demand on using contaminant-free tools, equipment, and as well as lab personnel entering the clean rooms. Most of the clean rooms are constructed with special materials such as steel, aluminum or similar materials in order to maintain the cleanliness with regular chemical wipe downs. Lab equipment and tools used are also subjected to wipe downs with chemicals and in some cases, the equipment needs to be sterilized and/or autoclaved. These stringent clean room requirements call for special RFID tags that can withstand the chemical wipe downs and sterilization or autoclaving processes. AssetPulse has deployed RFID lab equipment tracking software in a wide variety of clean room environments and has developed a clean room tracking solution that is proven to be effective.

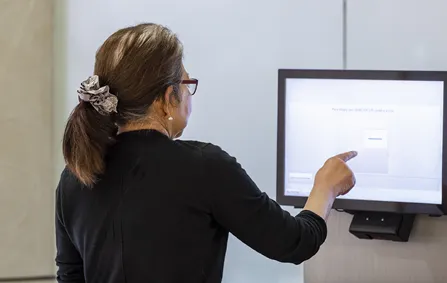

RFID Check-In/Check-Out Solution for Lab Equipment

Most of the labs have a significant number of high-value capital equipment that are purchased in necessary quantities and are therefore not available in volumes. Thus, it is essential to keep an account of what high-value equipment is taken out by whom and when it is expected to return. Capturing these details must be as simplified as possible so the scientists or engineers can record these details easily. AssetPulse's Check-In/Check-Out Solution is designed to make the tracking of high-value equipment and the associated details easy and hassle free.

RFID Laboratory Sample Tracking System

Biotech companies and laboratories invest millions of dollars on clinical trials and tests. Lab managers need to maintain sufficient inventory of equipment, as well as where exactly lab samples and specimens are to ensure that the trials are conducted as planned. Unavailability of equipment or samples will not only hamper project schedules but also can result in the loss of tens of thousands of dollars. Another major challenge that lab managers face is lack of visibility on lab sample/specimen movement. It can lead to sample mismatch resulting in wrong diagnosis, missing lab samples and delay in transportation. Lab managers cannot handle all these tasks manually. AssetPulse's RFID lab sample tracking system helps lab managers to track and monitor lab samples easily and efficiently. The laboratory sample tracking system also helps lab managers to effortlessly track compliance documents and stay on top of regulatory maintenance.

AssetPulse, with its years of working in labs and clean room environments, has tailored its RFID tracking solutions for this problem space. Whether the lab is serving engineers, as in Electronics or Mechanical Engineering labs, or scientists in Pharmaceutical or Chemical labs, the needs of the lab managers are similar. They would like to have important information readily available, including:

- Knowing which equipment is where

- Being able to easily search and locate equipment when it is due for calibration

- Being informed when equipment has moved locations - when and where to

- Knowing if an asset has not been 'seen' for a certain period of time and be alerted about it

- Knowing whether an item was 'checked out', but not returned

- Maintaining sufficient inventory of lab equipment and the location of samples, and tracking them accurately

- and a myriad other details

AssetPulse has worked with several Fortune 1000 companies worldwide, to deploy its AssetGather solutions in labs and clean rooms to give personnel real-time location status of their lab equipment.

Frequently Asked Questions

RFID Lab Asset Management Software is a solution that uses Radio Frequency Identification (RFID) technology to help laboratories track, manage, and locate their equipment efficiently.

RFID technology enables real-time tracking of lab equipment, allowing managers to easily locate equipment, monitor usage, and ensure timely calibration and maintenance.

Industries such as Electronics, Life Sciences, Medical Devices, Automotive, and Manufacturing can greatly benefit from RFID solutions due to their extensive R&D operations.

The software provides alerts for equipment due for calibration, helping lab managers avoid using equipment that has not been properly maintained, thus ensuring compliance with regulatory standards. Further, RFID handheld scanners can be used to help search and locate the equipment that is coming due for calibration.

AssetPulse's RFID solution includes real-time location tracking, check-in/check-out capabilities, alerts for movement, maintenance, and compliance document tracking.

Yes, RFID tags designed for clean rooms can withstand chemical wipe downs and sterilization processes, making them ideal for tracking equipment in these controlled environments.

RFID enhances visibility over lab samples, reduces the risk of sample mismatches, and ensures timely transportation, ultimately safeguarding the integrity of clinical trials.

RFID provides real-time data on equipment availability and location, helping lab managers maintain optimal inventory levels and reducing downtime.

Yes, most RFID solutions, including AssetPulse, are designed for seamless integration into existing lab workflows, minimizing disruption during implementation.

RFID can track a wide range of lab equipment, including high-value instruments, tools, and samples, regardless of their size or type. Further, samples can be tracked in refrigerated and cryogenic environments.

The cost can vary based on the size of the lab, the number of assets to be tracked, the RFID hardware infrastructure and the specific features required, but the investment often leads to significant long-term savings.